Our KSA catalog for automation and plant construction

In order to meet the requirements of the industry, the walkable cable tray system is subject to constant quality control in which the slip resistance as well as the load capacity are checked in order to guarantee our customers a high degree of safety. Especially for applications in automation and plant construction we have compiled an exclusive selection of Focus articles in the field of cable and cable routing systems as well as fastening technology.

All systems are made of high-quality steel and are also available in stainless steel versions. The various surface finishes ensure use both in dry interiors and outdoors or in aggressive environments. Accessories specially matched to the systems enable an installation-friendly and efficient laying technique. This allows horizontal and vertical directional changes to be made on site without any problems. The wide range guarantees that the most variety applications for cable routing can be covered.

Walkable cable tray

The system has been created as an innovative product for media guidance for rough use in the body-in-white production of the automotive industry.

With the application-related material thicknesses of the most important components in 1.5 mm or 2.0 mm, a side height of 60 mm, 100 mm, 110 mm and a wide range of accessories is the use of the BKS system also tailored to other industries in plant construction.

Wire mesh tray system MTC

This wire mesh tray system is mainly used in industry. Corresponding stainless steel versions are used in the food processing industry as well as in the food industry. Chemical companies, as the material meets the special requirements.

Due to a wire thickness of up to 5 mm, the products have a stable construction and can therefore withstand high loads. Many screwless system accessories allow a quick and easy way of assembly.

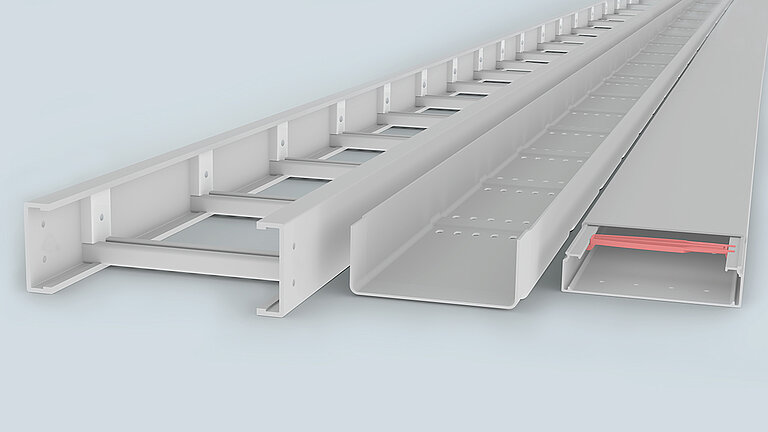

Cable tray system

The cable tray system offers maximum flexibility and economy. The wide range guarantees that the most varied applications for cable and cable routing are covered. Size and design can be called up individually, special dimensions available on request.

Accessories specially matched to the systems enable simple and flexible installation technology. Thus, horizontal and vertical changes of direction can be easily carried out on site. Functional integrity of electrical cable systems according to DIN 4102 Part 12, 1998-11 can be found in our KF catalogue.

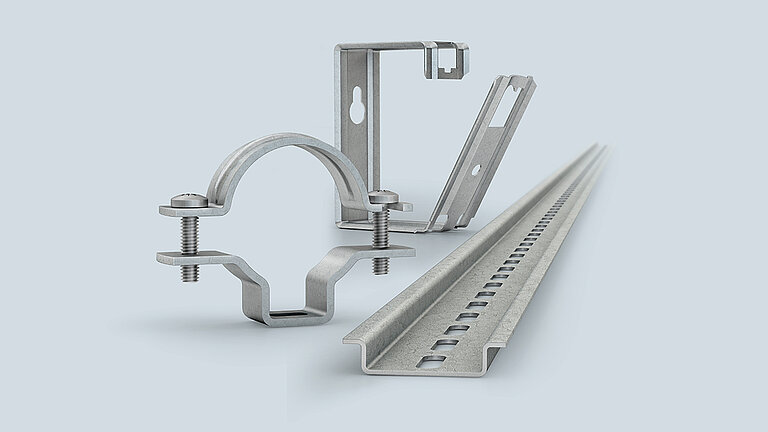

Support system

Compatible with the individual gutter types, we also offer the various supporting structures in several surface finishes. The range extends from strip galvanised steel to hot-dip galvanised steel and stainless steel.

Different dimensions with corresponding hole patterns as well as various support loads from light to very heavy design give you a free hand for individual attachment to the floor, wall and ceiling.

Vertical cable ladder system

The riser line system can be fastened directly by means of dowels without accessories and shows the same advantages as the cable ladder system: High loadbearing capacity due to the beam shape, stepless and drill-free screw connection of the wall connection parts thanks to continuous side beam perforation, quick fastening of the elements to be tensioned on the C-profile rungs by means of clamps.

The various materials and surfaces of the riser routes meet the corresponding corrosion protection requirements of the most varied areas of application

Cable trunking system

The cable protection / industrial duct system is mainly used in industrial areas and is used where increased protection against environmental influences is required. For example, it complements our walkable cable tray system (BKS), which is mainly used in the automotive industry.

The design of the industrial ducts enables cables to be routed to many end devices and consumers. Due to the systematically thought-out perforation with large cable outlets in the floor and on the sides, it is possible to lead cables out at any point of the duct.

Tools

In order to facilitate the conventional processing of the channel systems by sawing and cutting, we have included various cutting systems in the range. The benefits for the customer are time savings, reduction of rejects and cost savings. Channels and covers can be cut to length with low noise, precision and free of burrs in line with the contours.

The handy notching tools also allow lateral notching in various dimensions, even on channels that have already been mounted. With the battery-operated hydraulic wire mesh gutter cutter, wire thicknesses of up to Ø 6 mm can be processed.