RDRS cover system - Did you know that...

...our patented RDRS cover system is trend-setting for changes in the field of cable and wire routing systems in automation and plant engineering?

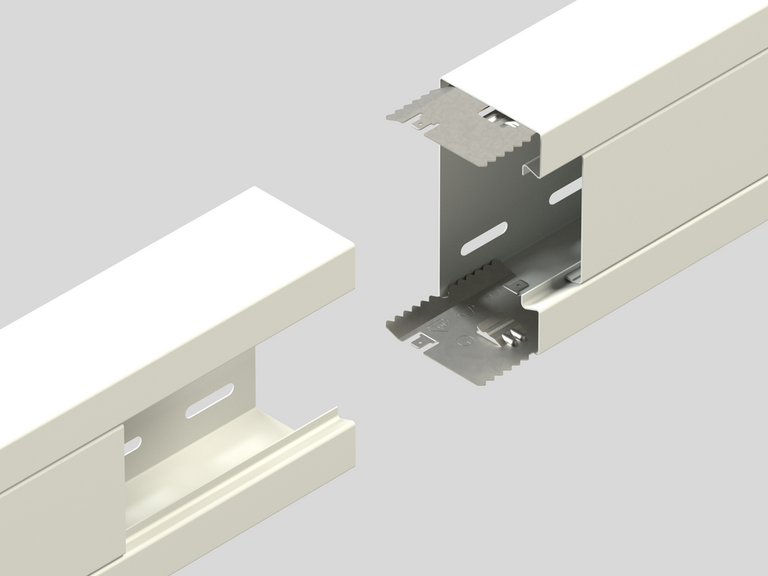

In the field of automation and plant engineering, cables often have to be laid directly or indirectly on the floor via branched routes between production facilities.

This type of installation requires a stable, robust and, in particular, a walkable cable trunking system with a slip-resistant cover to prevent accidents.

We avoid a separate aluminium layer and produce the lids directly with corrugation in a single operation. This means that the cover can be recycled after use and contributes to environmental protection.

During assembly, the system significantly reduces assembly time and allows channels and their lids to be cut without restricting their function. In short, the RDRS cover system is designed to maximise ease of installation.

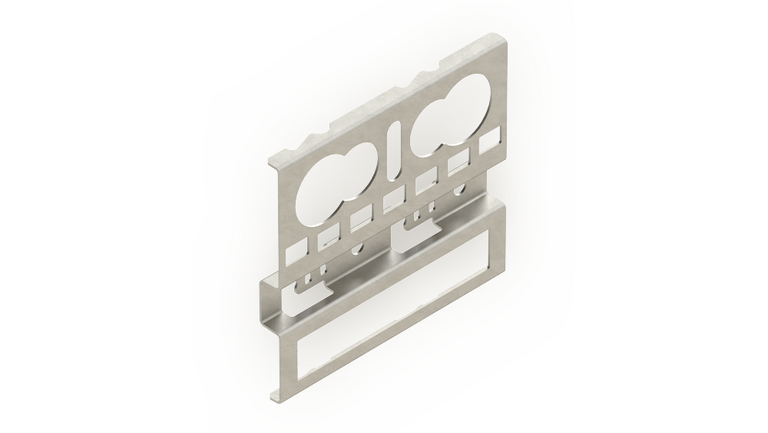

In the two-layer variant (aluminium + steel), the pre-assembled rotating bolts are removed by cutting and thus reduce the flexibility of the system. With this variant, it is very difficult to retrofit the turnbolt by drilling.

The continuous knock-out openings in the new patented cover system, on the other hand, make it possible to retrofit quarter-turns in the exact position required without drilling.

All you need for retrofitting is a hammer and a punch to open the break-out openings.

This means:

- A short installation time

- No special tools required (step drill)

- No chips due to drilling

- Precise positioning of the turn buckle

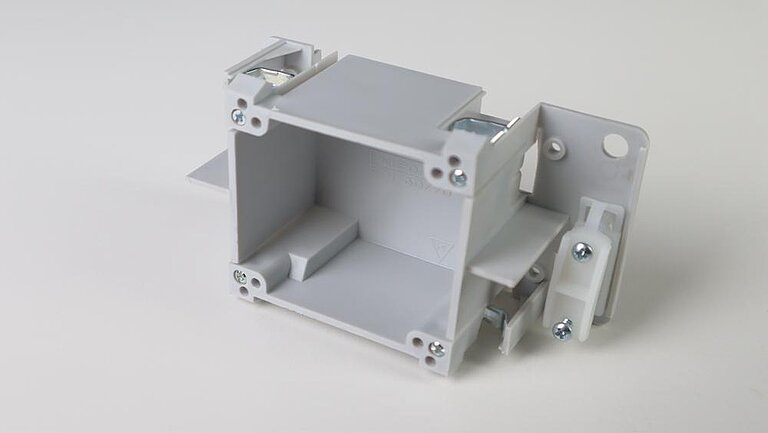

We also offer the DMT twist lock assembly tool to make the assembly of twist locks even easier.

A special feature is the side edges, which are free from embossing. This means that the covers can optionally be attached to the trunking using infinitely adjustable retaining springs.

The covers are available as standard in a strip galvanised version with a slip resistance rating of R10 in accordance with DIN EN 16165.

For projects with higher or other requirements, covers in hot-dip galvanised or powder-coated versions up to a slip resistance of R12 can also be supplied on request.

Please contact us if you have any questions on this topic.